Finding the Right Shaker for Your Test Application

How to Choose the Right Vibration Test Shaker for Your Application

When you need to test the durability or reliability of a product — whether it’s an electronics assembly, battery pack, automotive part, or heavy industrial component — selecting the right vibration shaker is a critical first step. The choice determines whether your tests will be meaningful, safe, and repeatable.

Here’s a detailed guide to help you decide.

1. Start with Your Test Requirements: Payload, Frequency, Displacement

Payload (Test Item + Fixtures)

The total mass you place on the shaker includes not just the device under test (DUT), but also fixtures, mounting hardware, head expanders, cables — everything that moves with the table.

Overloading a shaker reduces the maximum acceleration or vibration you can apply. In many cases, the shaker’s “force rating” (force = mass × acceleration) defines the limit.

Therefore, always start by calculating the worst-case total mass (DUT + fixturing + accessories) before narrowing down suitable shaker models.

Frequency Range

Different products and tests require different vibration frequencies. Some tests aim for low-frequency (e.g. transportation shock, large-structure resonance), others call for high-frequency stress (e.g. electronics, small assemblies).

Choose a shaker whose usable frequency range covers — and ideally exceeds — the highest and lowest frequencies you need. Using a shaker outside its optimal frequency range can yield unreliable or invalid test results.

Displacement (Stroke / Amplitude) & Acceleration / Velocity

If your test involves low-frequency vibration or shock, you may need larger table/stroke displacement (higher amplitude). For example, low-frequency sine or shock tests often require larger excursions.

On the other hand, high-frequency random or sine tests typically demand higher acceleration or velocity. The shaker must be able to deliver required acceleration at the payload and frequency. Because of the force-mass tradeoff (F = M × A), heavier loads reduce the achievable acceleration.

Therefore, ensure your chosen shaker supports the maximum displacement, acceleration, and velocity your application specification demands — for your payload and test profile.

2. Consider Table & Fixture Compatibility, Especially Slip Tables

If your test requires horizontal motions — e.g. vibration in transport direction, multi-axis simulation, or large payload shifting — a slip table (or multi-axis table) may be needed.

A slip table must be compatible with the shaker’s armature (mounting interface, force rating, mass, bearing guidance). If you mismatch these, performance degrades or test may fail.

On heavy or large-payload tests, pay special attention to slip-table bearing type, armature diameter, and isolation — to keep motion within controlled parameters and avoid destructive resonances.

3. Match Shaker Type to Application: Electrodynamic vs Hydraulic vs Others

For high-frequency vibration (hundreds to thousands of Hz), electrodynamic shakers are typically ideal. They provide precise control and fast response.

For low-frequency, high-mass, or heavy-displacement/shock applications, hydraulic shakers or long-stroke servo systems may be more suitable (though their frequency response tends to be lower).

If your requirements span both high-frequency and heavy-mass domains (or you expect to test very different kinds of products), carefully compare shaker specs — force, stroke, frequency, payload — or consider multiple systems.

4. Use the Right Control Systems & Test Profiles

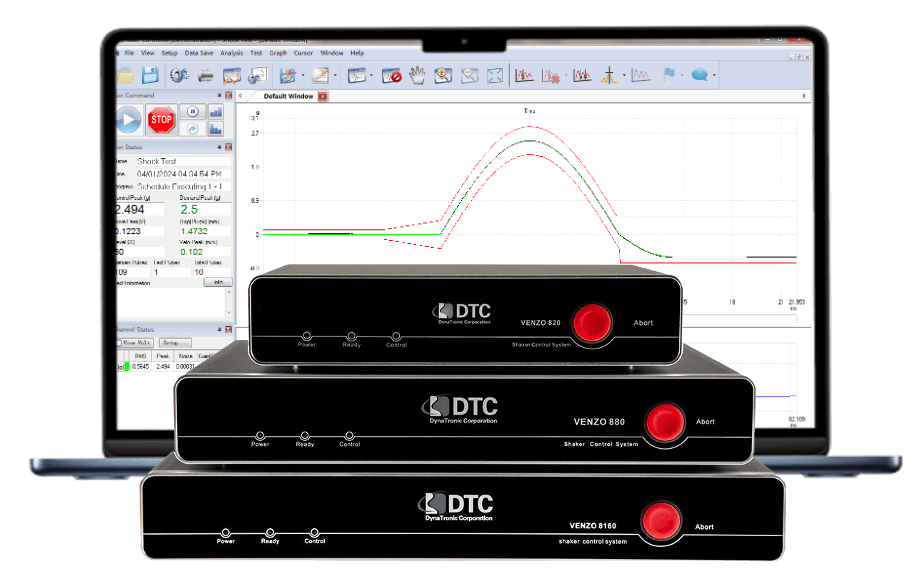

The shaker’s hardware must integrate with a control system (controller, amplifier, sensors, data acquisition) rich enough to produce the desired test profiles (sine sweep, random vibration, shock, etc.) and record meaningful data.

For repeatability and compliance (e.g. when using standard test methods), the control system should support precise control, feedback loops, and data logging. Poor control undermines even a “correctly sized” shaker.

5. Practical Example — Where ETS Can Help

Our H Series vibration shakers cover a wide range of applications. For example:

The ETS H1248A — usable with a slip table — offers robust performance for larger payloads (up to ~1,100 kg specimen mass), with sufficient armature diameter and displacement capacity.

For applications needing even greater stroke or “long-stroke shock / low-frequency test capability,” our LS Series can deliver large displacements while still maintaining usable frequency coverage.

For lighter or medium-size assemblies where frequency or precision matters more than massive payloads, smaller ETS shakers can offer high-frequency performance and precise control.

By consulting our model overview, you can match your test plan — whether it’s for electronics, battery packs, heavy machinery, or transportation-grade packaging — to the right shaker architecture, slip table option, and control system.

6. Key Questions to Ask Before Buying

Before contacting a supplier (or ordering a shaker), make sure you can answer:

What is the total mass of my test item + fixturing + cables?

What frequency range do I need for my vibration/shock profile?

Do I need large displacement (stroke), or high acceleration (or both)?

Will I need a slip table or multi-axis capability?

What mounting surface size and armature diameter do I require?

What type of shaker — electrodynamic, long-stroke, hydraulic — fits my application best?

Does the controller/amplifier support required test types (sine, random, shock, etc.), and provide accurate control and measurement?

If you can answer these, you’re on the right path to choose a shaker that meets your needs — not just today, but for future test campaigns too.

7. Conclusion

Choosing the right vibration test shaker isn’t just about picking the most powerful machine. It’s about understanding what you need to test — mass, frequency, motion type, displacement, table compatibility — and matching those needs to a shaker’s real capabilities.

At ETS Solution, our portfolio (L Series, M Series, H Series, LS Series, I Series, various slip-table and fixture options) lets you tailor the test system to your application — from small electronic assemblies to large industrial or automotive components.

If you’re unsure which configuration fits your test plan, feel free to contact us. We’ll help you evaluate requirements and suggest the appropriate shaker, slip table, and control setup.