Vibration Testing 101: Key Terms, Units & Methods Explained

If you’re new to the world of vibration testing, welcome! Whether you're working in automotive, aerospace, electronics, or energy—understanding how vibration affects your product is essential to ensuring durability, performance, and compliance with global standards.

This guide breaks down the fundamentals of vibration testing so you can feel confident in choosing the right equipment, interpreting test results, and improving product reliability.

What Is Vibration Testing?

Vibration testing simulates the real-world forces a product experiences during transportation, operation, or everyday use. These tests are conducted using vibration test shakers that replicate movements across various frequencies and forces.

Industries use vibration testing to:

Prevent early product failure

Validate design durability

Meet compliance standards (MIL-STD, ISO, IEC, etc.)

Improve customer satisfaction by reducing warranty claims

Key Terms & Units You Need to Know

Understanding the basics helps you interpret test specs and choose the right vibration test system.

Tip: The relationship between these parameters is important. For example, increasing frequency can decrease displacement but increase acceleration.

Types of Vibration Test Signals

Different test types replicate different real-world conditions. Here’s what you need to know:

1. Sine Vibration Testing

Purpose: Simulates predictable, smooth vibrations like engine hum or rotating equipment.

Test Example: Resonance searches.

Used In: Electronics, aerospace, automotive components.

2. Random Vibration Testing

Purpose: Simulates real-world chaotic vibrations like road bumps or turbulence.

Test Example: PSD (Power Spectral Density) profiles.

Used In: Military equipment, packaging, space systems.

3. Shock Testing

Purpose: Measures a product’s resistance to sudden impacts or drops.

Test Example: Half-sine, sawtooth, trapezoidal shock pulses.

Used In: Transportation, smartphones, aerospace gear.

Pro Tip: Many labs combine sine and random vibration tests (SRV) to simulate both constant and unpredictable forces.

What Happens During a Vibration Test?

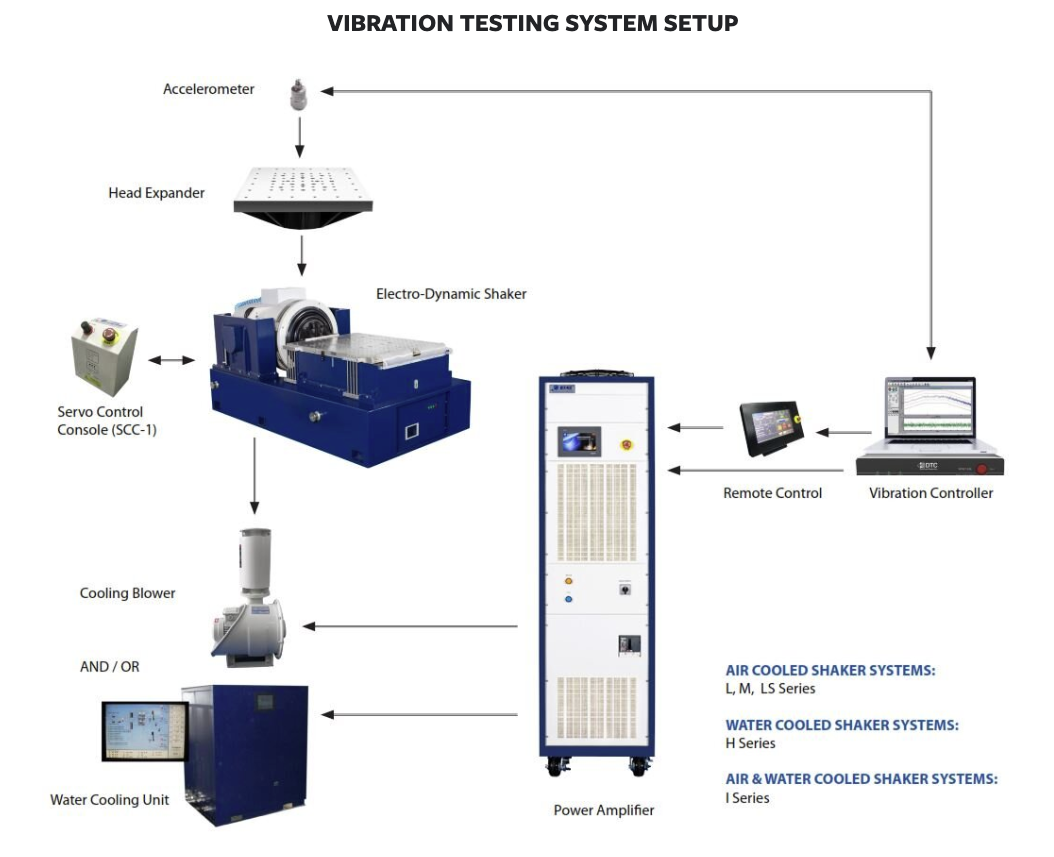

Here's how the process works using ETS Solutions' vibration test shakers:

Preparation: Mount the product on a test fixture connected to a shaker (horizontal or vertical).

Control Setup: Input a vibration profile (sine, random, or shock) using a vibration controller.

Execution: The electrodynamic shaker moves the product according to the profile.

Monitoring: Data acquisition systems or controllers track acceleration, force, and displacement.

Analysis: Engineers analyze results for fatigue, failure points, or compliance.

ETS Solutions: Reliable Vibration Test Equipment You Can Trust

ETS Solutions offers a wide range of electrodynamic vibration shakers—from compact tabletop models to high-force systems—designed to meet industry demands and international standards.

What Sets ETS Apart:

Precision-engineered shaker systems

Global support and service network

Seamless integration with environmental chambers

ISO, CE, and MIL-STD compliance

High-quality slip tables, amplifiers, and controllers

Ready to Get Started?

Whether you're testing an automotive sensor, aerospace component, or smartphone assembly, choosing the right vibration testing equipment is crucial.

👉 Need help selecting a vibration test shaker?

Contact ETS Solutions today or explore our product catalog.

✅ Summary: What You’ve Learned

Vibration testing is essential for product reliability.

Understand force, acceleration, frequency, and displacement.

Choose the right test method (sine, random, shock).

ETS Solutions offers the equipment and expertise to support your testing needs.